Dec 16 , 2024

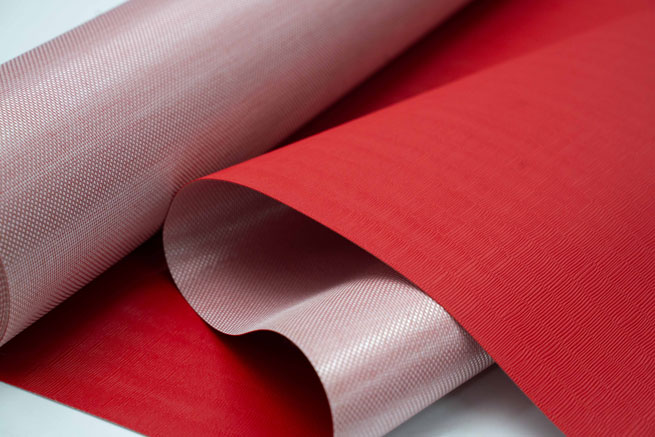

TPU (thermoplastic polyurethane) and PVC (polyvinyl chloride) have significant differences in raw materials and finished products.

TPU is a 100% environmentally friendly material that can be fully recycled, especially widely used in military and food safety applications. PVC is environmentally friendly and has the advantages of being very cheap, durable, easy to process, and easy to produce. It is one of the most widely used materials.

Comparing raw materials: TPU is an environmentally friendly material with excellent elasticity, wear resistance, and tear resistance, and does not contain plasticizers, resulting in a long service life. PVC is relatively economical, but it requires the addition of plasticizers to enhance flexibility, which may lead to hardening or embrittlement over time.

Comparing from the perspective of finished products: Products made of TPU are softer, more resistant to low temperatures, and more wear-resistant, making them suitable for high-end application scenarios such as medical and electronic packaging. PVC is commonly used in construction, advertising, and daily coverings, and is inexpensive and easy to process.

Overall, TPU is more environmentally friendly and durable, but the production process is complex and requires higher standards. PVC, on the other hand, is cost-effective and suitable for cost sensitive applications.